X-ray

Geissler

Crookes

Radio

Box art

Dr. Hugh Hicks

S.Slabyhoudek

M-Jay

Fort Myers, FL.

Monsieur Ara

Fin Stewart

Related links

Submit a link |

|

| Lamps of

Hiram Stevens Maxim |

|

Three carbon filament lamps exist in the collection that are identified as early Maxim types. Those lamps are shown in the gallery below. What follows are illustrations with descriptive text and advertisements taken from early technical books and electrical journals from the early days of incandescent lighting.

|

|

|

|

| [Sort: name hits] [Thumbs/Page: 8 12 16] |

|

|  |  |  |  |  |  |  | |  | c0036

Maxim

ca.1884

Hits: 1440

|

| c0133

Maxim

ca.1883

Hits: 805

|

| c0206

Maxim

ca.1883

Hits: 823

|

| |  |

|

|

|

|

|

General Information Series - Volume 2 By United States Office of Naval Intelligence |

1883 |

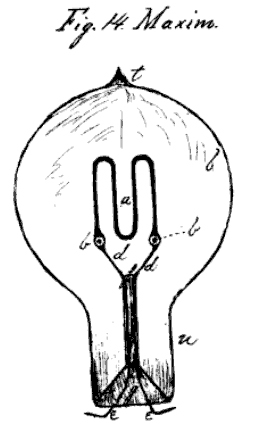

Maxim Lamp. (Fig. 14.)

The filament, a, is made of card-board. It is first cut out with a die from a very fine hard quality of board, and then carbonized at a white heat. After carbonization several filaments are mounted on loose clips, which project above a rubber cap, and complete, with the carbons, branch circuits from two mains. In the branch circuits are also included electro-magnets, whose armatures hold in place trip levers, which, on being released by the movement of armatures, fall and break the continuity of the individual circuits. Glass receivers or cups are inverted over the carbons, the mouths being closed by the rubber caps. Besides the wires in the caps, there are small tubes, all connected to one main tube. Through these the air is pumped out, replaced by gasoline, and a current sent over the mains. The carbonized papers, being of different resistances, are differently heated, and the resistance of all are lowered as the carbon set free by the decomposition of the gasoline is deposited on the incandescent filaments. As soon as the current in any branch becomes sufficiently strong, that is, the resistance reduced to a certain limit, the magnet in that circuit draws down the armature, frees the lever, and breaks its own circuit, the current in the others being unaffected. At first the fall of the levers is very irregular, but two or three exhausts and refillings of gasoline, with the passing of the current for the proper length of time, makes the fall of the levers practically simultaneous and the carbons are then ready for mounting. This process has made the carbons very homogeneous, and reduced them to one uniform standard of resistance. They are covered with a very hard skin and their durability much increased.

The platinum leading wires, de de, are imbeded a short distance apart in a rod of soft glass, f. The upper ends are flattened and crooked, and to these ends are secured the widened ends of the carbons by small platinum clamps, or nuts and bolts, cc. The lower end of the rod, f, terminates in the apex of a re-entrant cone, g, which closes the neck of the globe. The exhaust is by mercury pumps, while the carbons are gradually brought to a high incandescence. The lamps are well made, but the cost of manufacture can be somewhat reduced by using shorter lengths of platinum, and other fastening than platinum clamps. The lamps can be run at as high, if not higher, power than any other made. If the exhaust were made at the neck instead of at the top of the globe it would be better. The normal power of the lamp is 20 candles, and the resistance 44 ohms, which is too small for any wide spread distribution.

At the Crystal Palace there were 100 to 150 lamps, about 100 being maintained. These were supplied by a Maxim dynamo, the field magnets of which were excited by a second machine with movable commutator brushes. The lamps were run in the multiple arc system with two lamps as a unit.

The Maxim plan of distribution, whether with one or more lamps for units, is that of simple-multiple arc of main and derived circuits, as in Fig._. No meters or general arrangement for distribution were shown. The lamps when tested at low incandescence were very satisfactory. |

|

|

|

The Electric Light by Emile Alglave, J. Boulard, Thomas O'Conor Sloane, Charles Marshall Lungren |

1884 |

|

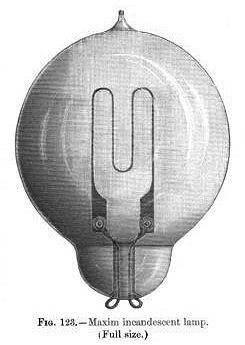

The Maxim Lamp.

[The lamp of Mr. Hiram S. Maxim has the same general features of those above described. The filamentary conductors are stamped from paper, and have the form of the letter M, instead of a simple loop. They are carbonized between sheets of paper in iron molds, and are afterward subjected to a treatment to render them as homogeneous as possible. Mr. Edison abandoned paper as a material for his incandescent filaments because of the difficulty of getting it homogeneous. Mr. Maxim endeavored to overcome this defect by heating the filaments to incandescence in a carbonaceous atmosphere. The gas is decomposed by the heat of the filament, and the liberated carbon deposited upon it, those parts which are thinnest, and consequently hottest, receiving the heaviest deposit.

Filaments of very uniform conductivity can be produced in this manner, and any form of carbon can be so treated. A rarefied atmosphere of gasoline-vapor is that usually employed, and the deposit is commonly made in a separate vessel before the filament is mounted for sealing in the final globe, though it can be readily effected while the lamps are on the mercury-pump before the final exhaustion is completed. This method of equalizing the resistance of a filament is also used by Lane-Fox, and an analogous one was employed by Sawyer and Mann.

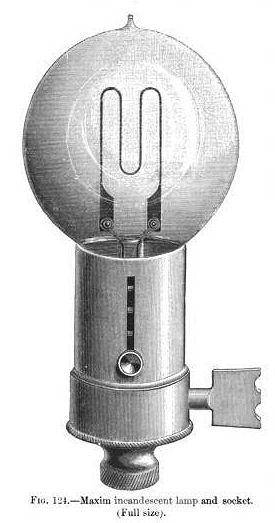

The platinum leading wires are attached to the filament by a species of clamp. The ends of the filament are enlarged, as are also those of the leading wires. The two are then clamped together by means of a minute bolt provided with a nut passing through each- a remarkably expensive mode of attachment. The leading wires are sealed into the glass of the globe, as in the other lamps of this kind. The appearance of the complete lamp is shown in Fig. 123, and the lamp mounted in its socket, in Fig. 124.] |

|

|

|

The Electrician and Electrical Engineer

|

Sept. 1884 |

|

|

Report on the International Exhibition of Electricity Held at Paris, August to November 1881

by Army, David Porter Heap, United States Army. Corps of Engineers, United States |

1884 |

THE MAXIM LAMP.

To form the filament of the Maxim lamp, a piece of bristol-board is first cut in the shape of the letter M, with rounded angles; it is then slightly carbonized and placed in a glass globe filled with the vapor of gasoline; the current is then passed through the filament and the gasoline is decomposed, depositing carbon on the filament. As the thinnest part of the filament will be the most highly heated by the current, the most carbon will be deposited at that point, and the filament will become homogeneous; this process is continued until the resistance has been decreased to from 40 to 60 ohms; a vacuum is then produced until the pressure does not exceed .00001 of an atmosphere; the slight portion of vapor remaining will act as a renovator should any one part of the filament remain thinner than another.

The two ends of the filament are prolonged by two platinum wires, which are soldered to the glass globe by means of a kind of bluish cement, resembling enamel, in the mass of which the wires are introduced, and, as this cement attaches itself strongly to the glass, there is no danger of affecting the vacuum by the contraction or dilation of the wires.

The inventor states that these lights are each of 26 candle-power; that six of them can be maintained per 1 horse-power, and that their duration is from six hundred to nine hundred hours.

An ingenious switch attached to each lamp lights or extinguishes it at will. The lamps are so made that they can be placed in their supports or removed from them with as much ease as a candle. The lamps are all placed in derived circuits; each is perfectly independent of the others. At London they were placed in ordinary gas brackets, the gas-pipe serving to carry the return current. The main cable is composed of nineteen copper wires 1.6 millimeters in diameter; to this cable those of less size are attached, and the diameter of the wires is gradually reduced to .85 of a millimeter, which supplies 6 lights, the wire of each light being .3 of a millimeter in diameter. In case of a sudden increase of the current, this last-mentioned wire will fuse before the platinum of the lamp, which will, therefore, not be injured. |

|

|

The Principles and Practice of Electric Lighting by Alan Archibald Campbell Swinton

|

1884 |

The Maxim Lamp.

In the Maxim lamp the filament is made of carbonised cardboard in the form of the letter M. In section it is rectangular and several times as broad as it is thick. Carbonisation is performed in a mould. After it has been fitted into the lamp globe the filament is strengthened by the deposition of carbon from gasoline in much the same manner as in the process employed by Lane-Fox, the lamp globe being filled with the gas, and the filament heated by the passage of an electric current. The heat decomposes the gasoline, and carbon is deposited upon the surface of the filament. Since those parts of the filament which are thinnest are most highly heated, the carbon is more rapidly deposited upon the weak points, and the filament is thus strengthened and rendered of equal resistance throughout. |

|

|

Knight's new mechanical dictionary By Edward Henry Knight |

1884 |

|

|

Arc and Glow Lamps By Julius Maier |

1886 |

|

The Maxim Lamp.

The filament, which is of the shape of an M (Fig. 83), is made of carbonized cardboard. The globe is exhausted, and a certain quantity of hydrocarbon vapour (gasoline) introduced, then the globe is again exhausted whilst the current passes, and the operation repeated until all the air is expelled. It has been proved by experience that by the passage of the current the rarified vapour of gasoline has a renovating effect, by depositing its carbon on the most incandescent, that is to say, the thinnest parts of the filament. The filaments are connected to the platinum pincers by means of soft carbon, which gives an excellent contact. The conductors are sealed into a special enamel which has nearly the same coefficient of expansion as platinum; this prevents cracks and contributes to the tightness of the apparatus. The lamps are fixed to an ebonite mounting, which terminates in a pedestal of German silver; this latter can be screwed on a gas-bracket instead of an ordinary burner. |

|

|

The Incandescent Lamp and Its Manufacture by Gilbert Scott Ram |

1894 |

|

|

|

|

|

|