A few years ago a 2000- or a 2500-watt incandescent lamp seemed large; but now, as the result of developmental work, 10,000-watt lamps are manufactured and are regularly used in the motion-picture industry, airport lighting, and in some other places where high intensity illumination is desired. To date, the largest incandescent unit that has been attempted is the 120-volt 50,000-watt lamp, of which only a few have been made, for special illumination and display. These have operated successfully and the strength of the various parts has allowed the lamps to be shipped from coast to coast without any breakage; thus it has been demonstrated that a successful 50-kw lamp can be made if necessary.

Sometimes comparisons and figures are given concerning these large lamps without any real conceptions as to what the figures really mean. To make a lamp to make a lamp that will consume 50-kw requires some very special construction, for this is really a large amount of energy - it would take almost the entire output of a 70-hp engine to furnish enough electricity to operate one of these lamps. This amount of power would operate 500 to 1000 lamps such as are regularly used in our reading lamps. Also this amount of power would be sufficient to operate enough incandescent lamps to light satisfactorily a mile of city thoroughfare.

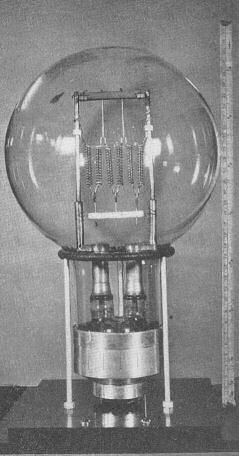

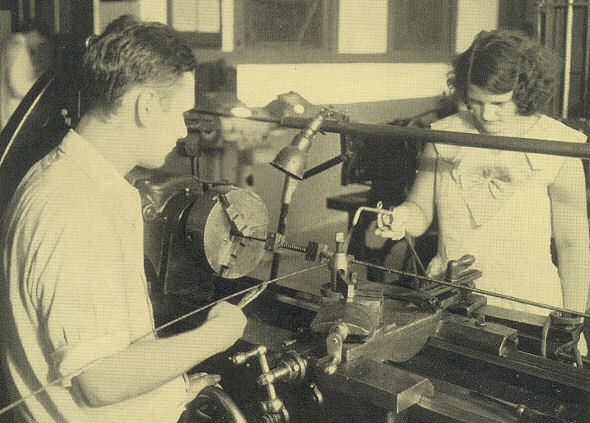

A picture of the 50-kw lamp is shown in Fig. 1. The filament, like that of all gas-filled lamps, is coiled and in this lamp it consists of six segments mounted in a plane. The filaments for the ordinary 40 to 100-watt gas-filled lamps are coiled by machinery at a rate of three to five thousand revolutions per minute. It is much more difficult to wind a coil of tungsten wire of the size necessary for the 50,000-watt lamp. The method used in the winding of this coil is shown in Fig. 2. It is to be noted that a large machine lathe is used and that an iron rod about three-eighths inch in diameter is used as the mandrel. To wind the coil it was found necessary to heat the tungsten wire to a dull red with a blast torch as shown. One complete segment and about one-half of the next one are shown on the mandrel. The picture also shows the large clamps used while winding the coil to hold the ends and the straight portion of the filament between the coils. This wire as shown was coiled on the lathe by hand at a speed of about fifteen revolutions per minute.

At first a great deal of trouble was experienced due to the cracking of the seals when they were made similar to the ones used for the smaller lamps, i.e., two pieces of tungsten sealed in the glass press. To overcome this trouble it was found necessary to use copper-to-glass seals for these large lamps. This solved two very troublesome problems: the one already spoken of, i.e., the cracking of the seals; the other, the method of carrying the filament and its supports. The filament and its supports are so heavy (about 6½ lb.) that it was found practically impossible to support them in the usual manner by means of the leads sealed through the glass press. With the copper-to-glass seal the filament and its supports are carried on heavy copper rods passing through the copper tubing that is joined to the glass, as shown in Fig. 1. The bulb and the filament with its leads are both supported by the large base shown in the picture. The complete 50-kw Lamp weighs over thirty-five pounds.

Fig.1 Complete 50kw lamp. At the right of the

lamp is shown a 36in. scale to indicate the size.

It was not found practical to make the bulbs of the 10 or 50-kw lamps as large in proportion to their wattages as the smaller lamps. Thus the radiation through the bulb is several times greater for these large lamps than for the smaller ones and this caused the bulb to operate at a high temperature. For this reason it was found necessary to use pyrex for the bulbs. These large lamps are designed for a service where the primary consideration is a great amount of light. For this reason they are designed for 100 hours of life, since a tungsten filament has a higher efficiency at the high temperature corresponding to this life, and thus much more light can be obtained from the same size filament.

Fig.2 Illustrating method used for winding coils for the 50kw lamp.

If the glass blackens from the vaporization of the tungsten it will become much hotter, since the blackened glass absorbs a larger percentage of the energy that falls upon it, than the clear glass. If this is allowed to continue the glass becomes so hot that it may soften and blow out at this point, causing the lamp to fail. To overcome this difficulty a small amount of coarse tungsten powder was put into the bulb to scrub off the black deposit. Thus by shaking the powder around in the bulb periodically, the life of the lamp is very greatly increased. It is now the general practice to clean these large lamps after about every twenty hours burning.

The weight of the filament for the 10-kw lamp is about 39 grams and for the 50-kw lamp about 740 grams. The amount of tungsten used for the filament in a single 50-kw lamp is sufficient to make about 120,000 forty-watt filaments. The bulb for the 10-kw lamp is spherical in shape and about 12 in. in diameter, while the one for the 50-kw lamp, also spherical, is about 20 in. in diameter.

Fig. 3 shows the form of mounting used for a 50-kw. lamp that was on display on top of the Lexington Building at Baltimore during Light's Golden Jubilee in the fall of 1929. Fig. 4 shows a picture of one of these lamps and the mounting that was on display at the 1930 N.E.L.A. Convention at San Francisco.

Fig.3 The 50kw lamp as mounted on the Lexington building

at Baltimore during Light's Golden Jubilee, 1929.

Fig.4 The mounting used with the 50kw lamp that was

displayed at the 1930 N.E.L.A

convention at San Francisco.

In Table 1 are given some of the characteristics of the 10kw and 50kw lamps.

It is interesting to compare some of the characteristics of the largest and the smallest lamps now manufactured. The smallest lamp made is the "grain-of-wheat" used for surgical purposes. A picture of one of these small lamps is shown on the small vertical rod just at the right of the center at the bottom of the picture of the large lamp in Fig. 1. It is so small that it appears as a point. This small lamp has as a bulb a small tube about 2 mm. in diameter and about 8.7 mm. long. The complete lamp weighs 0.06 grams.

The horizontal candlepower of this little lamp is 0.028 as compared to 166,000 candles for a 50-kw lamp. The temperature of operation of the grain-of-wheat lamp is 2100 deg. K., while the large lamp operates at a temperature of about 3300 deg. K. The small lamp operates from a single dry cell and consumes 0.17 watts. Thus it is seen that the wattage of the large lamp is about 300,000 times that of the smaller and the amount of light radiated by the 50-kw lamp is about 5,000,000 times that of the little lamp. The tungsten used for the filament of the 50-kw lamp would make filaments for about 21,000,000 of the little lamps.